Industrial Automation Controls Engineers, Technicians and Electricians

Industrial Automation Specialists are responsible for designing, improving, and supporting systems in manufacturing and process plants. They work with Industrial Automation devices like Programmable Logic Controllers (PLC), Distributed Control Systems (DCS), Supervisory Controls (SCADA), Industrial Ethernet Switches (IES), Human-Machine Interfaces (HMI), variable frequency motor drives (VFD), and a wide variety of networked actuators, sensors, and other IIOT. Most of these devices can be connected with Industrial Ethernet copper and fiber cables running a variety of industrial protocols like ProfiNET, EtherNet/IP, Modbus-TCP, EtherCAT, and CC-Link.

When something goes wrong in a process, the Controls Engineer or Industrial Electrician is often called in to determine if the problem is related to control logic, devices, or the Industrial Ethernet cable between devices. Controls Engineers support a wide variety of equipment and processes and need tools to determine if problems are in the network cable, the devices, or device configurations. Click here to learn more about our Industrial Ethernet Cabling resources.

Industrial Automation Controls Engineers, Technicians and Electricians

Key Issues

Isolating Industrial Ethernet Problems

Customers tell us that over 50% of Industrial Ethernet network problems are related to the cable (copper or fiber). Cables are sometimes made wrong, are too long, poorly terminated, susceptible to corrosion, vibration, and electrical noise.

Machines stop working or on lights indicate a problem. Network diagnostics and link LEDs usually indicate roughly where the problem is, but do not isolate the issue to a specific device, device configuration or cable.

The most common method to isolate a problem is trial and error. Basically, replace items until the problem clears. This method is time-consuming, especially when the machine stops intermittently.

Intermittent Problems - EMI

Electromagnetic Interference (EMI) generated by Variable Frequency Drives (VFD), motors, contactors, and solenoids are not supposed to disrupt Industrial Ethernet data frames (also called packets). Industrial Ethernet cables are supposed to be immune to this noise and not let EMI damage data frames. However, not all cables are made for this environment, are damaged, or maybe installed wrong. Moisture, vibration, and temperature changes can also cause weak cables to fail intermittently.

In one recent example, a material handling line with 20 VDFs stop when one particular VFD was turned on. After three days of analysis, it was determined that the VFD was operating correctly, but a short cable routed near the VFD output cable had a defect that caused ~10% of the ethernet frames to have errors when the motor was running.

Commissioning a New Machine

The Industrial Automation network is one of many elements that can delay the installation of a new machine or cause downtime during the acceptance period. Often copper and fiber optic cables are installed and not tested at all. When the machine does not work or stops working after a while (especially in an EMI environment), the engineers and installers have to troubleshoot for every possible problem. If they tested the cables and eliminated any cable problems, they would significantly reduce the about of troubleshooting and commission their system faster.

Ask Our Experts

Jim Davis

Regional Marketing Engineer, North America & Latin America

Jim Davis ha estado trabajando en el sector de cableado por más de 25 años. Durante los últimos 18 años, ha trabajado en Fluke Networks, primero como director de ventas para Latinoamérica, y más recientemente como ingeniero regional de marketing.

Jim has worked on International Cabling Standards Committees, is a frequent speaker at industry trade shows and has participated in dozens of manufacturer’s conferences.

Jim’s objective is to bring the experience of the Industry, the Market and the Lab to you and present it in way that the common user can understand.

Wayne Allen

Ingeniero regional de marketing, Asia-Pacífico

Wayne es un miembro experimentado del equipo de Fluke Networks y ha sido asociado con productos de Fluke y Fluke Networks durante los últimos 26 años en muchos roles diversos. Currently Fluke Networks’ Product Marketing Engineer for the Asia Pacific Region, Wayne is responsible for pre-sales technical support for Fluke Networks products within the region.

Wayne initially joined Philips Scientific and Industrial Electronics in 1989 (the then agents for Fluke in Australia and New Zealand – Wayne went on to became part of the Fluke team in 1990). Antes de incorporarse a Philips, pasó 12 años con el Departamento de defensa en diversos roles técnicos como especialista en comunicaciones militares.

Christian Schillab

Regional Marketing Engineer, Europe & Middle East

Christian Schillab ha estado trabajando para Fluke Networks Europa desde 1997 como ingeniero de marketing para productos de comprobación de medios. Como miembro de los estándares alemanes DKE/GAK 715.3.2 y AK 651.2.1 participa activamente como experto en los temas de comprobación de campo y componentes y antes de eso en el foro de FrameRelay y ATM. Previously, he has worked for various North American manufacturers of Telecom Test & Measurement products, namely Spectron, NAVTEL and Nextest - in various sales, marketing and market development positions for Europe, Middle East and Africa.

Related Resources & Downloads

Industrial Ethernet networks are the backbone of many of today’s connected factories and Industrial Automation systems. El cableado, ya sea de cobre o de fibra óptica, es una causa importante del tiempo de inactividad en estas redes de control industrial sensibles al tiempo.

Entendemos que, como electricistas de planta, técnicos de instrumentos o ingenieros de control, una de sus principales prioridades debe ser evitar el tiempo de inactividad. When something goes wrong in a process, it’s not always easy to determine if the problem is related to control logic, devices, or the Industrial Ethernet cable between devices. Aquí hemos reunido una serie de recursos que lo ayudarán a comprender mejor cómo validar, resolver problemas y mantener su cableado para determinar rápidamente si hay problemas en el cable de red, en los conectores o en los dispositivos. Make sure you’re doing everything you can to prevent line downtime and to get back up and running quickly if problems do arise.

Videos

-

Video: Easier Industrial Ethernet Troubleshooting by Fluke Networks - Learn how to pinpoint and solve cable problems faster in your Industrial Ethernet environment.

-

Vídeo: Faster Industrial Ethernet Installs by Fluke Networks - Learn how cable testers can speed startup and uncover problems before they affect your network.

-

Vídeo: Testing M12X with the DSX CableAnalyzer - See how the rugged M12 Connector can help you validate the performance of these connections to avoid problems when starting up a new line and prevent unscheduled downtime.

-

Vídeo: Industrial Ethernet Cabling – Testing the “E” in MICE - See how to test the three levels of “E” Electromagnetic susceptibility to performance specifications.

-

Vídeo: Choosing the Right Limit for Industrial Ethernet Testing - Whether you’re testing M12 or RJ45, it's critical to select the right limit for your industrial ethernet cable connector. This video discusses different standards and how to test against them using the Versiv / DSX CableAnalyzer™.

Documents

Are you interested in learning more about Industrial Ethernet Cable validation, troubleshooting or maintenance? Estos recursos lo ayudarán a comenzar con los consejos y estándares rápidos que debe conocer.

-

Póster de referencia técnica: Industrial Ethernet Cable Testing - This digital poster will give you a quick reference to Industrial Cable Topologies, ethernet cable connectors, and more.

-

Obtenga más información sobre: Industrial Ethernet Copper Cabling - Learn about cabling standards and testing to avoid those difficult to troubleshoot start-up delays and set yourself up to maximize your Industrial Ethernet uptime.

-

Documento técnico: Industrial Ethernet Standards Paving the Way for the Next Industrial Revolution - Make sense of the Industrial Ethernet buzz words and standards and how they fit in your world of industrial controls.

-

Folleto de productos: Soluciones de comprobación de cables de Ethernet industrial: conozca los productos de comprobación de cables de Ethernet industrial que ofrece Fluke Networks. Feel free to contact us directly to discuss the solution that’s right for you.

-

Industrial Ethernet Cable Field Test Requirements - Developed in conjunction with Rockwell Automation, provides users, consultants and engineers with a guide to developing contractual specifications and executing cable tests for new Industrial Ethernet copper network deployments or major retrofits.

Support

Fluke Networks has an extensive group of experts ready to help you with your pre and post-purchase needs.

-

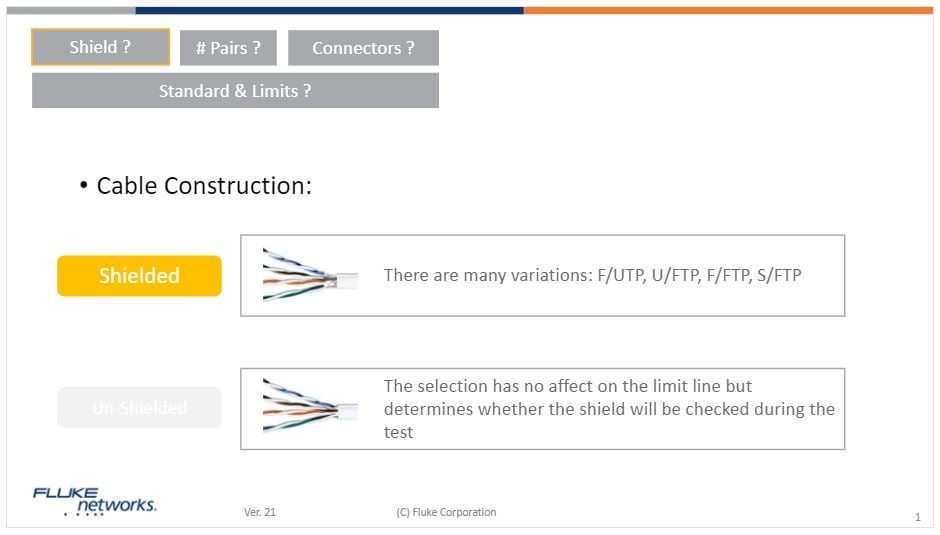

Guía interactiva: Testing Industrial Ethernet Cabling with the DSX CableAnalyzer - This interactive guide will help you to determine how to set-up your DSX CableAnalzyer for the Industrial Ethernet cable testing you want to perform.

-

For technical support, call 1 (800) 283-5853 or visit http://www.flukenetworks.com/Support